China, 19th Dec 2023 – In the ever-evolving landscape of electronics, the importance of PCB (Printed Circuit Board) technology cannot be overstated. Within this dynamic field, one manufacturer stands out as a trailblazer in innovation and quality – Best FPC. Join us as we explore the latest breakthroughs in PCB technology and discover the role of Best FPC in shaping the future of electronic devices.

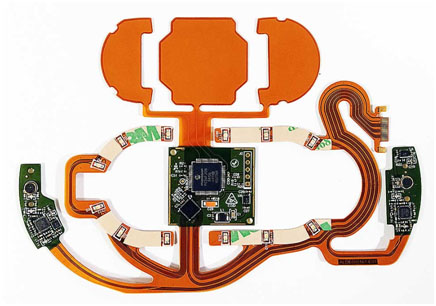

Bendable Circuit Board

Bendable circuit board, also known as flexible PCBs or FPCBs, are electronic circuit boards designed to be pliable and adaptable to various shapes. They consist of a flexible substrate, often made of polyimide or polyester, on which conductive traces are etched. These boards are used in applications where traditional rigid PCBs would be impractical or restrictive.

Key Features and Applications

Bendable PCBs offer exceptional flexibility, allowing them to conform to 3D shapes and fit into tight spaces. They find applications in:

- Wearable devices: Conform to the body for comfort.

- Curved displays: Enable innovative screen designs.

- Automotive interiors: Fit complex contours for integrated electronics.

Advantages of Rigid PCBs

Compared to rigid PCBs, bendable PCBs provide numerous advantages, including:

- Space-saving: Ideal for compact and miniaturized devices.

- Weight reduction: Lightweight design benefits various industries.

- Enhanced durability: Fewer solder joints result in higher reliability.

- Improved signal integrity: Reduced electromagnetic interference.

Rigid Printed Circuit Board

Rigid printed circuit board are traditional circuit boards with a rigid substrate, typically made of fiberglass or epoxy resin. They are the foundation of electronic devices, providing a solid platform for components and connections.

Typical Use Cases and Industries

Rigid PCBs are found in a wide range of industries and applications, including:

- Consumer electronics: Smartphones, laptops, and gaming consoles.

- Industrial equipment: Automation systems and control panels.

- Aerospace and defense: Avionics and mission-critical electronics.

Strengths and Limitations

Rigid PCBs offer stability and robustness, making them suitable for many applications. However, their rigidity can be a limitation in designs requiring flexibility or 3D integration, which is where bendable PCBs shine.

4-Layer Rigid-Flex Stackup

A 4 layer rigid flex stackup combines the benefits of both rigid and flexible PCBs. It consists of multiple rigid layers interconnected by flexible sections, offering a versatile platform for complex electronic designs.

Benefits in Terms of Design and Integration

- 3D integration: Enables folding or bending within a device.

- Reduced complexity: Fewer interconnects than traditional rigid PCBs.

- Space optimization: Ideal for applications with limited room.

Real-World Applications and Advantages

- Medical devices: Compact designs for diagnostic tools.

- Automotive control units: Space-saving solutions in vehicle electronics.

- Aerospace applications: Weight reduction without sacrificing reliability.

Flexible Printed Circuit Board

Flexible circuit manufacturers, as the name suggests, are designed to be flexible and adaptable. They are commonly used when space constraints, complex geometries, or dynamic motion are involved.

Versatility and Applications in Modern Electronics:

- Medical devices: Conform to anatomical shapes in wearable health tech.

- Robotics: Facilitate joint movement and cable routing.

- Automotive: Enable sensors and control units to adapt to vehicle shapes.

- Key Benefits in Terms of Space-Saving and Adaptability:

Flexible PCBs offer key advantages:

- Space-efficient: Can be folded or bent to fit tight spaces.

- Reduced weight: Ideal for applications sensitive to weight.

- High reliability: Fewer interconnects and solder joints reduce failure points.

Rigid PCB Manufacturer – Best FPC Striving to Meet Your Requirements

Best FPC stands as a prominent figure in the PCB industry, boasting expertise across a wide spectrum of PCB categories, encompassing rigid, flexible, and rigid-flex PCBs. Our commitment to customer satisfaction is unparalleled. Upon receiving your RFQ, we prioritize a swift response, ensuring you receive the most competitive quotation within a mere 12 hours. Additionally, our adept engineering team is at your service, offering tailored design support and specialized technical assistance for your flexible PCB requirements.

Should you lack a design file, rest assured that we can recommend the most suitable design solution for your needs. Furthermore, we take pride in our “Quick Turn” prototype service, capable of delivering FPCs to you in a week or less, often exceeding expectations. For those with even more urgent demands, we offer a 72-hour quick delivery service. Our global reach extends to customers in over 100 countries worldwide, a testament to our dedication to meeting the diverse needs of our valued clientele.

Media Contact

Organization: bestfpc

Contact Person: peter

Website: https://www.bestfpc.com/

Email: Send Email

Address: 5F, Bld7, Hengmingzhu Technology Industry Park, Xingqiao Tongfuyu Industry Zone, Gonghe, Shajing Town, Baoan District, Shenzhen,China

Country: China

Release Id: 1912238398

The post Advancements in Flexible and Rigid PCB Technology by Leading Manufacturer – Best FPC appeared first on King NewsWire. It is provided by a third-party content provider. King Newswire makes no warranties or representations in connection with it.

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Sahyadri Times journalist was involved in the writing and production of this article.